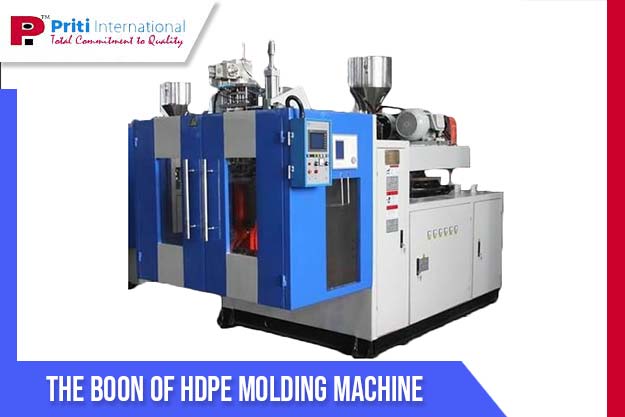

The process of molding plastic injection is very reliable, simple and versatile which produces top grade components and parts of plastic. The HDPE molding machines are extremely efficient and hold a high ability to manufacture and produce plastic goods that are not only cost-effective but also premium grade and eco-friendly. This machine is undoubtedly one of the smartest inventions of humankind. Youngsters nowadays are leaning more towards the field of business and the manufacturing sector yields a good amount of profit. It is beneficial for both the economy and the people. The more business, the more employment opportunities and more profit. Considering the demand of plastic goods, manufacturing them is an excellent idea. That is why you need the HDPE molding machine. It has a lot of benefits. Let us know more about them.Â

A Brief About HDPE Molding:

The concept of HDPE first came into existence in the United Kingdom somewhere around 1930. It was first put to use by radar cables. With the introduction in the United States later, it became very popular and since then everyone is in love with the great features and technology that it has. This makes it the perfect choice for commercial and industrial applications.

A polyethylene thermoplastic which is constructed from petroleum is HDPE. The physical properties of HDPE are highly strenuous, strong, versatile and very dense. The popularity of these machines just keeps growing and shows no signs of fading away anywhere in the near future. Plastic goods are extremely high in demand due to their variable uses from piping systems to food containers. You can mould them in any size and shape. Plastic has the ability to withstand weather and environmental changes without being damaged. Hence, both the parties- one making them and one using them are at an advantage.

People prefer this because they are weather-resistant, lightweight, recyclable, durable, hygienic, affordable and approved by the FDA.

The Widespread Use Of PVC:

One of the most common thermoplastics that the industry uses for manufacturing plastic goods is PVC or polyvinyl chloride. They use this to make several products like containers, pipes, electrical cables, storage system, medical tubes, etc. Since the demand for plastic goods is soaring high, one should select the best quality of polyvinyl chloride when choosing the item. It will help you produce the finest quality of products. There are plenty of advantages of using PVC. They are very strong, durable, lightweight, easy and convenient to use, reasonable, eco-friendly, non-toxic, resistant to fire, etc.

The Rising Popularity Of Plastic Injection Molding:Â

This process is a favourite among many people due to its speed. As a result you can get a huge bulk of products in a very less amount of time. This increases the productivity and output of a company yielding high profit. It is extremely malleable and flexible as well. Hence, minute products can also be manufactured without a lot of waste.

If you want to venture in this business, then we recommend getting in touch with Priti International as they are truly the experts. They will provide you and set you up with everything you need. They are also the leading providers of PVC moulding machines. Check out their website for more information.