In the effervescent world of fruit juices, the journey from orchard to glass is a symphony of flavours and investments. For entrepreneurs looking to plunge into the refreshing domain of fruit juice processing, understanding the nuances of project costs is pivotal. Let’s embark on a journey through the complexities of fruit juice plant project cost in India, and uncover the secrets of succulent ventures.

1. Plant Capacity and Scale:

The size and capacity of the juice plant play a pivotal role in determining the overall project cost. From small-scale units catering to local markets to large-scale facilities targeting widespread distribution, the capacity choice influences equipment needs, space requirements, and, subsequently, the project cost.

2. Location Dynamics:

The geographical location of the juice plant introduces cost variations. Factors such as land prices, availability of utilities, and transportation infrastructure impact the overall project cost. Kolkata, with its strategic location, emerges as a promising hub for fruit juice processing ventures.

3. Technological Infrastructure:

Embracing cutting-edge technology in juice processing enhances efficiency and product quality. The cost of acquiring advanced machinery, processing equipment, and automation systems contributes significantly to the overall project expenditure.

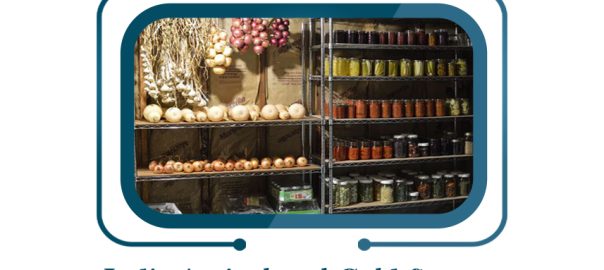

4. Raw Material Sourcing:

The source and quality of raw materials, primarily fruits, impact project costs. Establishing relationships with reliable fruit suppliers and ensuring a consistent supply chain are essential considerations.

5. Labor and Manpower:

Skilled and efficient manpower is indispensable in the juice processing industry. The cost of hiring and training staff, as well as ongoing labour expenses, adds to the project budget.

6. Compliance and Licensing:

Adhering to regulatory standards and acquiring necessary licenses are non-negotiable aspects of setting up a juice plant. The costs associated with compliance measures and obtaining permits contribute to the overall project expenditure.

7. Utilities and Operational Costs:

Utilities such as water, electricity, and fuel are essential for the continuous operation of a juice plant. Evaluating the availability and costs of these resources is crucial for financial planning.

8. Packaging and Distribution:

The choice of packaging materials, branding, and distribution channels impact the final project cost. Considerations for attractive, functional packaging and efficient distribution networks are vital for market penetration.

Fruit Juice Plant in Kolkata: Priti International’s Expertise:

In the vibrant landscape of Kolkata, Priti International stands as a beacon of expertise in setting up fruit juice processing plants. With a rich legacy in providing turnkey solutions for diverse industrial ventures, Priti International offers comprehensive guidance and support, ensuring a seamless journey from project conceptualization to fruition.

Final Words

Understanding the dynamics of fruit juice plant project cost in India, especially in dynamic cities like Kolkata, empowers entrepreneurs to make informed decisions. With Priti International as a trusted partner, the journey becomes not just a business endeavour but a flavorful odyssey, capturing the essence of India’s vibrant juice industry.