A cattle farming is a very beneficial businesses nowadays. If you already have the resources, you can initiate a business to make a source of revenue.

A lot of people are opting for poultry and cattle feed plant business, cattle farming as an occupation. As cattle’s farming is a very huge industry, one needs a lot of enthusiasm, patience before he starts the business. Let’s have a look on the essentials about cattle farming.

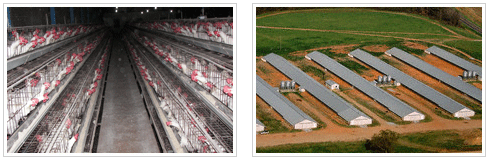

• Make sure that you are starting the business small initially. After buying or inheriting the farm, don’t spend a huge amount of money. If needed, think about repairs, renovations for important things such as the house, handling facilities.

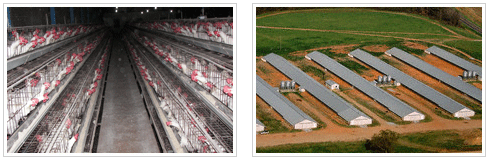

• Plan what kind of chickens, ducks, turkeys, geese, and cows you want, and what kind of farm you wish to manage.

• You can purchase essential machinery at an auction. You can buy the essential equipment and other items according to your need. As you grow your business, get equipment accordingly over the time.

• If you don’t have much capital to start with, settle on low cost producing.

• Make sure you have settled all the resources that you need – land, breed, water and food supply. There are sudden variables that could come into play when you are farming cattle.

• As change of weather can affect the condition & result of the cattle, make sure you are using proper protection according to weather. Keep your firm hydrated in summer, and warm in winter.

• Make sure that you have resource of water for your cattle to drink.

• Make sure you have enough of storage food, lots of hay to feed your domestic animals.