An HDPE molding machine refers to the process of molding a soft thermoplastic hollow known as Parison. Gain an overall understanding of HDPE by reading this blog.

Most turnkey project consultants use Parison by vertically extruding it from the Die Head. It exists inside the Blow Molding Machine and inflates against a cooler surface. This expanded plastic further solidifies into a hollow HDPE product that requires very little finishing procedures. Particularly, after the blow molding process.

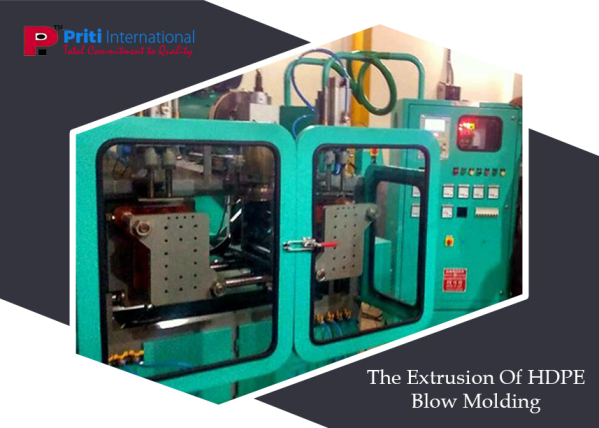

Types Of Extrusion Systems In HDPE Blow Molding Machines

Generally, two types of extrusion systems exist in HDPE blow molding. The first one is Continuous Extrusion and the second, is non-continuous extrusion. The latter consists of an accumulator’s head as well. To know which HDPE extrusion system is enough for the product, you have to undergo a lot of considerations.

Firstly, the key exists in the size as well as the weight of the product. The amount of HDPE Material is important for its production. We generally call it the shot size. Moreover, the shot size refers to the weight and length of the Parison in a PVC molding machine. Ejection takes place from the extrusion die head of the machine.

In a Continuous Extraction Blow Molding system, the Parison constantly extrudes during the blowing procedures. As a result, the weight and size of the product should not be very big. It will need a larger shot size and can make it complex to control the temperature. Both the top and bottom of the Parison receive a constant temperature.

On the other hand, the melting plastic chamber goes into the Accumulator head in a non-continuous system. After this process, they vertically extrude between 2 clampings plated in a single shot. Having a high injection speed helps in closing the 2 clamping plates and so, the blowing cycle begins.

How Does Accumulator Head Help In Blow Molding Machines

Firstly, the accumulator’s head helps in better controlling the Parison’s temperature. When it’s time to close the mold, the plastic Parison gets ejected at once. As a result, the blowing cycle begins. This indicates that the Parison must not be kept outside for a long time. Its constant temperature makes it a high-quality product.

The structural design of the blow molding machine lets the clamping unit have a stronger clamping force. For turnkey project solutions, this force must be distributed equally along the clamping plates. This avoids any air leakage during production.

Conclusion

This was all about an HDPE PVC molding machine. Are you thinking of buying one? Then, get in touch with Priti International. They deal with projects focussing on a turnkey basis in Kolkata. So, head over to them today and purchase PVC and HDPE machines at affordable prices.