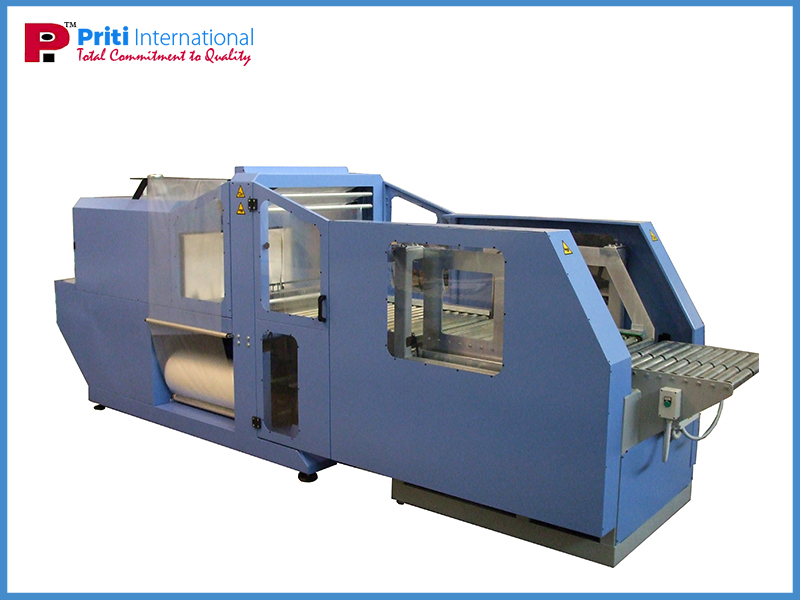

Are you looking for the wrapping something? Then you need to use the fully automatic sleeve wrapper in order to pack several thousands of commodities per day. Toy starts with the I bar sealers or manual impulse sealers, the company often offers newer types of wrappers. Costing only a little hundred dollars, these wrappers are very productive machines which can be used by the owners. The project consultants recommend the setting up of this type of machine, as the production and business grows. Over the impulse sealers and I bar sealers, this machine offers several benefits. Let’s look at the production and cost levels and multiple other advantages of the machine.

Are you looking for the wrapping something? Then you need to use the fully automatic sleeve wrapper in order to pack several thousands of commodities per day. Toy starts with the I bar sealers or manual impulse sealers, the company often offers newer types of wrappers. Costing only a little hundred dollars, these wrappers are very productive machines which can be used by the owners. The project consultants recommend the setting up of this type of machine, as the production and business grows. Over the impulse sealers and I bar sealers, this machine offers several benefits. Let’s look at the production and cost levels and multiple other advantages of the machine.

Benefits:-

Bar Sealer-

With an L bar, which is designed with more efficiency than I bar sealers, semi-automatic sleeve wrapper machine is manufactured. In one motion, the L bar sealer cuts and seals all open sides. To make the final seal, and I bar sealer or impulse sealer is needed for the users to rotate the product after the first seal.

Magnetic Hold Down-

There is a magnetic hold down options, which are being offered by the I bar sealer and impulse sealer manufacturers. With a magnetic hold down, a semi-automatic sleeve wrap equipment is designed. To complete the seal, the magnetic hold down holds the sealing bar down. This assists the users to start the preparation for the next level of products.

Discharge Conveyor-

On the semi-automatic sleeve wrap device, the discharge conveyor is an admirable time-saving feature. Between the L bar sealers, the discharge conveyor is found. After the magnetic hold releases, the conveyor carries products from the sealers to the sleeve tunnel.

Sleeve Tunnel-

Over the manual machine, a sleeve tunnel is by far the most time effective benefit to a semi-auto- machine. To apply heat to the film, most of the companies’ advances from the manual sleeve wrap are often using one or several heat guns. In the entire sleeve wrapping process, this step can drive the longest number of time and people crazy. Through a heated area, the sleeve tunnel uses a conveyor to transport products. The finished products exit the shrink tunnel, as the film is heated and shrunk.

Micro Knife Band Ribbon-

With wire sealing elements, most of the impulse and I bar sealers are constructed. Then the band ribbons, most of the wire sealers often burn out and need fast replacement.

Conclusion:-

Sleeve wrappers are the most interesting machines used in the packaging industry. The turnkey consultants of “Priti International” will tell you about the working and installation.