What is one of the largely significant regulations of food manufacturing, aside from creating safe and high-quality products?

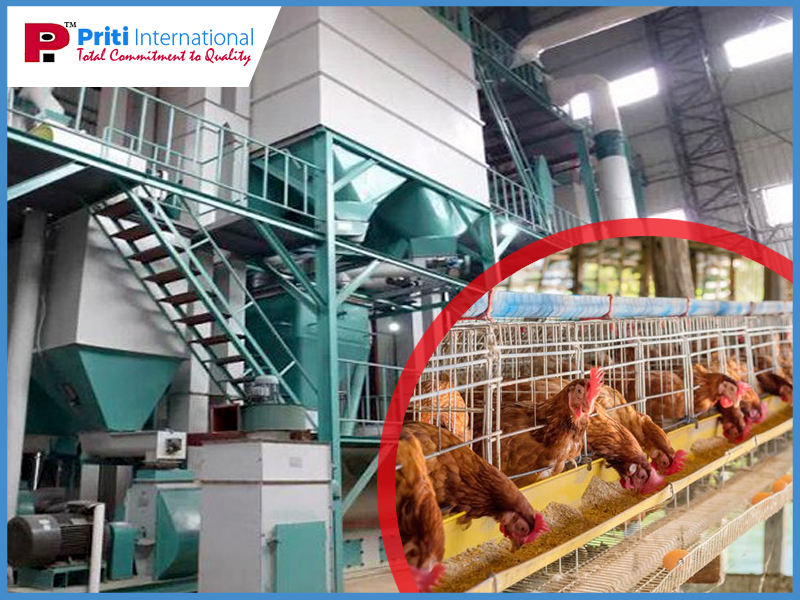

The readers need to have a clear understanding of how chicken feed plant in Kolkata can work if there is a breakdown in machinery. The design of food processing unit can be a tedious and lengthy one, but often one forgets when the critical decisions are to be taken. In addition to anticipated optimal workflow and production volume, the engineers will assess the needs of the plant and will look at the sanitation requirements and product manufacture. But what can happen, if suddenly the plant machinery started to go down? But the first one needs to recognize which exact parts of the plant are untreatable. Is it food dealing out facility and packaging portion or both? Or is it manufacturing area. If so, then, there are three key solutions, which will ensure that the plant will keep on running. They are co-packers, Co manufacturers and Built-In redundancy.

You can always take the help of the experts if the plant machinery is facing severe failure problems and don’t leave it until it is too late.

Co-packers:-

One should think about engaging a contract packer, normally referred as co packer if the packaging system of the food processing plant in Kolkata is down. The contract packer is also referred to as co-packer. Working under the contract to pack the product, as if it approached from the client, a co-packer packs the product for the client.

Co Manufacturers:-

One should think about engaging a contract producer, known as a contract manufacturer if the facility’s manufacturing is out of order. Creating it as if it came from the client, co-manufacturers and co-workers develop the products for the client below contract. There can be certain questions which may come into one’s mind.

*These are –

i) Are they equipped and tooled to produce the product?

ii) How elongated can they carry on the orders?

iii) To align with the current expectations, are their HACCP programs in-house superiority control supervised and enforced?

Built-In Redundancy:-

Due to the trade secret, company culture or competitiveness, if co-manufacturing or co-packaging is not a choice for the company and then during capital planning, one needs to believe adding redundancy in the operational network. This is a choice more appropriate for multi-provision companies, due to the cost. By plant capabilities, one should ensure sales and operation in the aligned position.

Conclusion:

Since an emergency is not planned and if any natural disaster in the plant breaks out and depreciated the machinery, then to find the solution, one may contact the experts of Priti International who will tell you the solution from the situation.